Process and Materials

Konekt strives to deliver products that reflect our commitment to high quality design, materials and craftsmanship. Our intention is to engage the senses through natural materials, textures and patinas. Natural materials and hand-applied finishes are subject to variation in color, pattern and texture. Images of material and finish options can be found on each product page.

Konekt’s designs combine both modern and centuries old techniques to achieve an elevated, contemporary aesthetic. Below are some of the processes that highlight the ethos of Konekt’s collection:

Hand-Sculpted Metal

Our Stone Collection features sculptural metal forms that are entirely sculpted by hand. These asymmetrical, complex shapes require a labor-intensive process and a high level of skill and sensibility. Strips of sheet metal are welded together and then sculpted through repetitive hammering, stretching and smoothing. The result is a seamless functional sculpture with uniquely soft curves and contours, reminiscent of stones tumbled by the ocean.

Upholstery

Each of our upholstered pieces are expertly hand-stitched in Pennsylvania. Sculptural forms with deep curves, such as our Pause Chaise Lounge and Pause Lounge Chair, require exceptional craftsmanship. The mastery of upholstery and hand-constructed furniture is also evident in our Thing collection, from the making of wood frames and horse hair wefts to the seamless blending of these materials with fabric.

Sand Casting

Our cast metal pieces are sand cast at a fine art foundry in Pennsylvania. Sand casting is an ancient casting process which utilizes sand as the mold material. A wood pattern is first made in the shape of the object or component, and then the pattern is encased in sand to create the sand mold. The process is completed by pouring hot, liquid metal into the mold, occupying the negative space to create the final form.

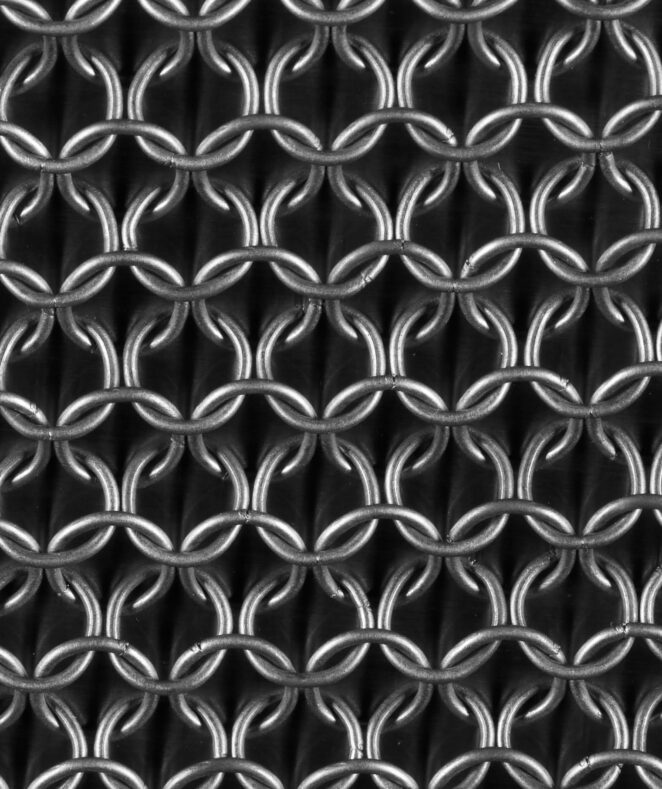

Chainmail

Konekt’s Armor Collection features furniture and lighting designs that are draped in cloaks of stainless steel chainmail. Working with an American company that has been producing chainmail since 1876, we create chainmail patterns to hug the shape and size of each design. Panels of chainmail are made by machine, and then joined by hand to create a pattern. We’ve established our own unique finishing process, allowing us to offer extensive finish options for clients to choose from.

Wood Work

Our wood pieces are hand-built by master craftspeople in Pennsylvania, and meticulously made with hand-selected woods. Each piece is built with great attention to detail, from hand-shaped table tops resembling organic forms to three-dimensional cabinet doors handwrapped in goatskin parchment. Our wood finishes are applied with a multi-step process to enhance the wood and provide a durable finish.